I didn't know how the process to emboss worked and it was one of the questions on my 'to do' list, so I attended a workshop to find out.

Tips/things to consider:

Text below below 10/12pt will struggle to work.

Takes 7hrs to etch the plate.

Bold sans-serif fonts work better.

The larger the surface of coper, the longer it takes to expose.

For an indented finish, making the plate out of wood with the laser cutter is quicker and works better.

For a proud finish, copper etching is more effective.

To prepare the plate you need the image printed on acetate in black and white.

-Expose the image onto the light sensitive film > Settings: 9 light units

-Sand the plate the create a surface for the film to sick to > wash and blot dry

-Dont touch the plate > place acetate on the plate

- Wind the plate through the press > rotate the plate 90 degrees and rewind through the press > trim the access film

- Drop sodium carbonate into 3 litres of water

-Clear of the clear layer of the film and place in the solution.

-Sponge every 30 sections until the copper is exposed.

-Rinse with cold water and blot dry.

-Tape up the back of the plate and place in the acid and leave to etch for 7 hours turning about half way through to allows the copper to dissolve evenly.

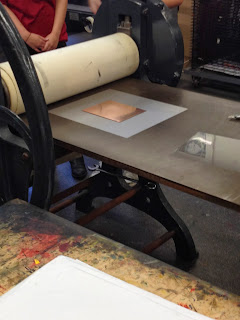

-To emboss place the stock on the plate and cover with a layer of tissue.

Tighten the screw towards you and pump the handle, once its tight, press the black button and continue pumping the handle until it becomes difficult.

Examples on different stock

No comments:

Post a Comment